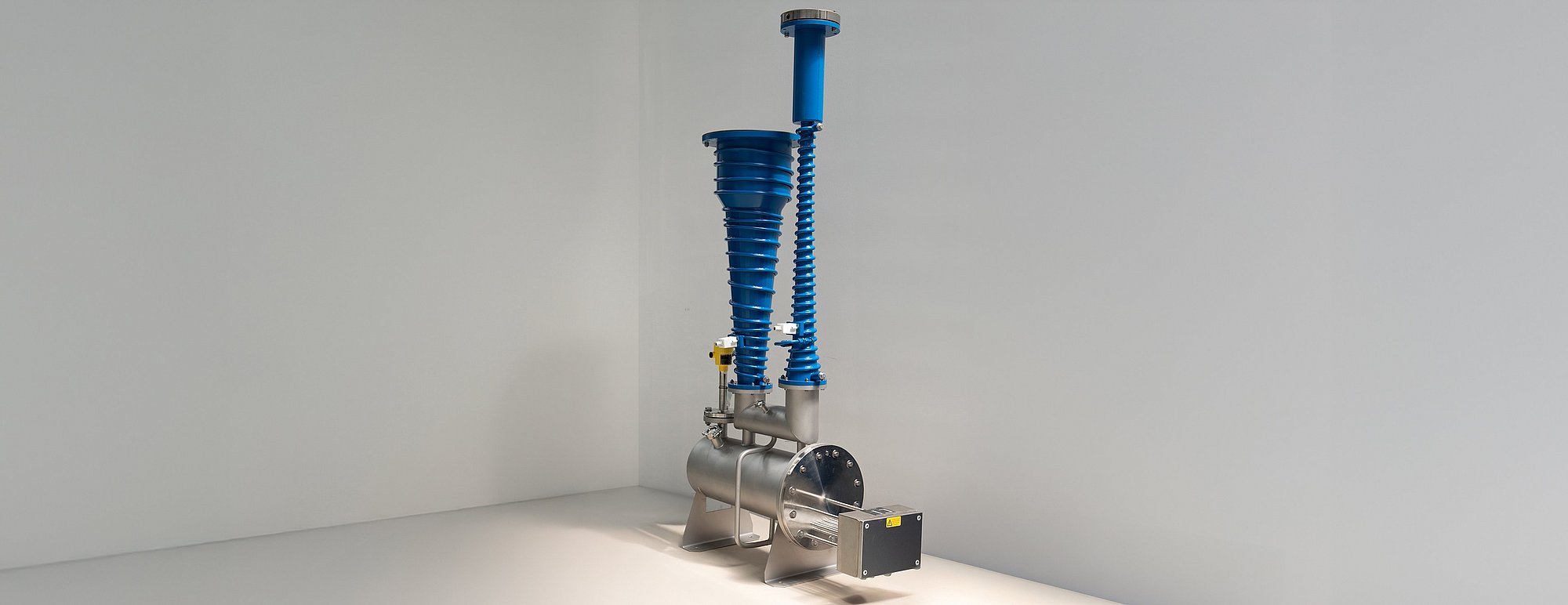

VTA’s new “V-Boost” offers a high suction capacity and excellent throughput, even at very low operating pressures.

The Diffusion Booster Pump ensures quick pump-down times for improved efficiency.

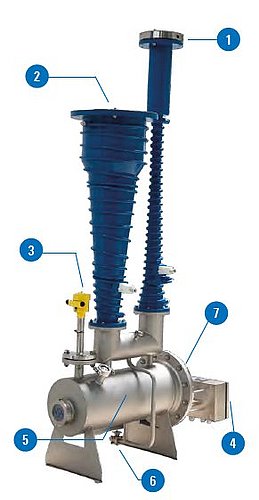

1: Pressure side

2: Suction side

3: Level switch

4: Cartridge heater flange

5: Boiler

6: Drain

7: Main boiler flange for easy access

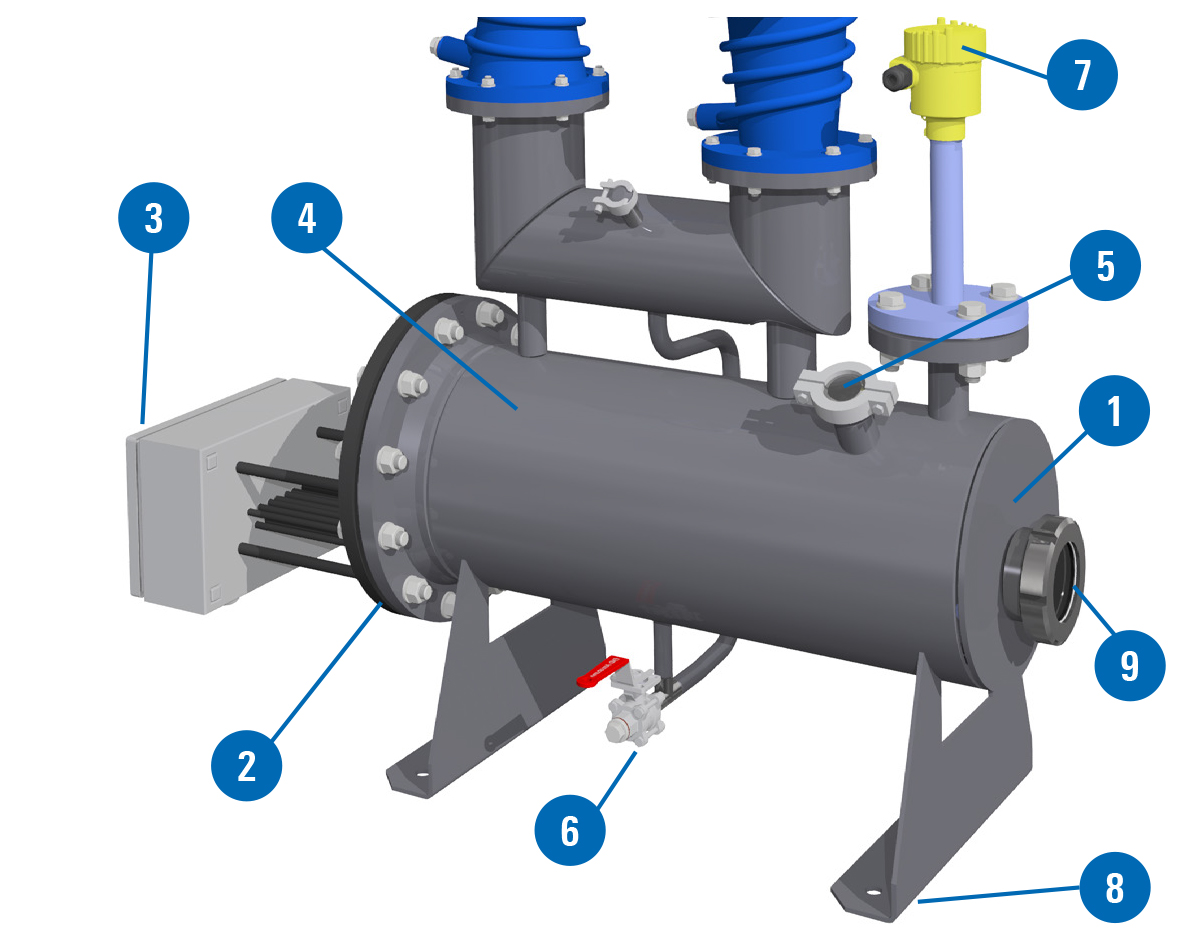

1: Full stainless steel boiler

2: Easy-accessible boiler for cleaning

3: Cartridge-type heating elements, easily removable

4: Boiler easily isolatable to minimise heat losses

5: Easy refilling

6: Full drainability at the lowest position of the boiler

7: Low level switch in boiler vessel

8: Accurate bracket support

9: Sight glass to enable inspection of boiler and booster fluid

ATEX version available! Compact design!

Any questions?